July 11th, 2014. It is a persisting opinion amongst some window producers, that warm edge would only have marginal influence on the heat loss through a window. Quote from the interview with a window manufacturer, printed in the German glass magazine GLASWELT 5/2014, page 58: “Und so viel Energie geht doch nicht über diesen Kanten-Unterschied verloren.” – “And it is not that much energy that is lost through that difference in edge bond.“

Good gracious! Maybe this was valid in former times, when thermal transmission coefficients of windows were on rather humble level. For window U-values of more than 2 W/m²K, the improvement by use of warm edge systems was not that much. During the past years though, windows went through an enormous evolution in thermal performance. Nowadays, Uw-values of windows for new buildings in Germany are in the range of approx. 1.1 to 0.8 W/m²K, and this Uw-value is for the whole window, including frame and thermal bridge at the glass edge – not only a center-of-glass value. By rule of thumb, the use of warm edge instead of conventional aluminium or steel spacers improves the Uw-value of wooden- or PVC windows by approx. 0.1 W/m²K – or for metallic windows up to 0.2 W/m²K. Considering that approximately reveals that the effect of warm edge is easily in the range of 10 % – of the overall energy losses through a window, note well!

But for all that, in new windows aluminium spacers still do occur, even if it is triple glazing. What a pity, to pass up the chance for improving the Uw-value. Why? Is it just a lack of knowledge or making false economies? After years of educational work on this area I have no more understanding for that. Compared to other measures for thermal optimization of windows, warm edge is simple to implement and in addition extremely economical. Once the new windows are installed without warm edge, they will stay like that for the next decades. The potential for energy saving is lost for a long time.

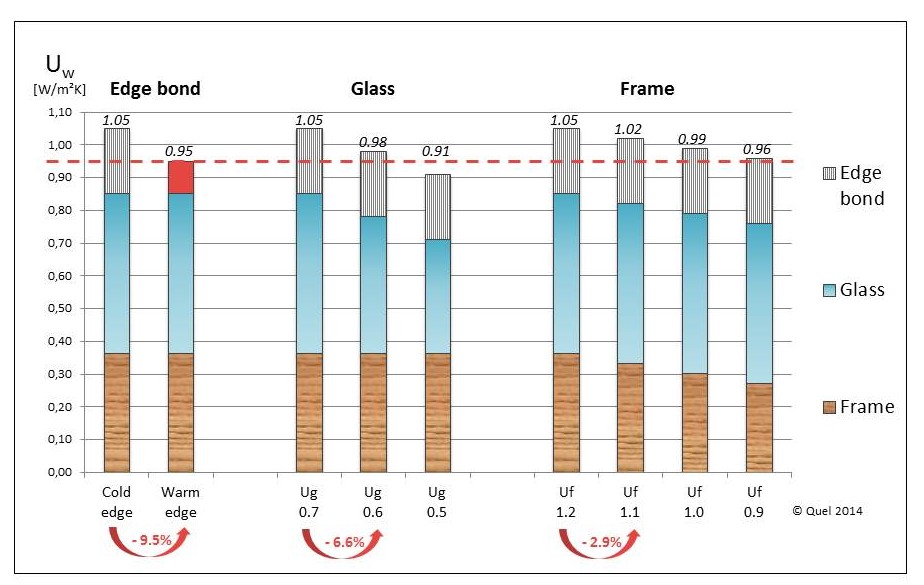

This graph shows the energy losses of a single-winged window and how they are shared between the three window components glass, frame and edge bond. Furthermore it illustrates the potential for optimization. Starting point is a window with the dimension 1.23 m x 1.48 m, a frame share in the total window area of 30 %, an Uf-value of 1.2 W/m²K and triple glazing with an Ug-value of 0.7 W/m²K and edge bond with aluminium spacers.

The comparison shows the possible extent of improvement of the Uw-value through

– warm edge instead of conventional aluminium spacers

– improvement of the Ug-value of the glass area

– improvement of the Uf-value of the frame area

If you want to know more about that, you can read my article (in German language) in the

GFF-magazine of march 2014 here .

Letzte Kommentare: